do you think you're trying to optimize your drilling operations and minimize downtime? Among the most important factors impacting efficiency will be the shaker screen. selecting the proper display can significantly have an impact on mud circulation, solids removing, and General cost-effectiveness. This information will offer you the important information needed to make an informed decision and choose an ideal shaker screen to your precise demands, making sure your drilling operations operate effortlessly and efficiently. As a leading shaker display screen manufacturer, we realize the value of high quality and performance Within this critical location.

Table of contents:

essential things to look at When picking a Shaker display screen

Different Types of Shaker Screens as well as their programs

How the proper Shaker monitor Can make improvements to Drilling effectiveness

critical components to take into consideration When Selecting a Shaker Screen

choosing the correct shaker monitor requires thorough consideration of many variables. to start with, the kind of drilling fluid getting used performs a big part. Water-based mostly muds demand unique mesh measurements and more info display screen constructions when compared with oil-primarily based muds. Second, the scale and sort of solids currently being eradicated are very important. Finer solids involve finer mesh screens, but these will also be a lot more prone to blinding. 3rd, take into account the stream amount and tension from the drilling fluid. substantial move rates can place tension over the display, potentially bringing about premature failure. last but not least, Appraise the shaker's compatibility with different display screen sorts. Not all shakers can accommodate all screen styles, so confirming compatibility is critical. thinking about these essential elements can help you narrow down your choices and choose a shaker screen that optimizes your drilling operations. as an example, if you are using a VSM300 shaker, explore choices such as the corrugated a single-piece steel sheet alternative screens from trustworthy suppliers.

differing kinds of Shaker Screens and Their purposes

Shaker screens appear in many different styles, Each and every suited to distinct apps. Woven wire mesh screens are a standard decision, featuring a price-efficient Alternative for getting rid of a variety of solids. Composite screens, produced from various levels of mesh and guidance supplies, give Increased toughness and finer filtration capabilities. Pyramid screens, with their three-dimensional area, give elevated screening spot and improved circulation capability. Hook strip screens are suitable for quick set up and replacement, minimizing downtime during screen improvements. Pre-tensioned screens are stretched and bonded to a frame, furnishing consistent stress and improved functionality. Understanding the strengths and weaknesses of each style will enable you to pick out the best choice in your drilling ecosystem.

How the proper Shaker Screen Can increase Drilling Efficiency

the proper shaker display screen range directly interprets to improved drilling performance. Effective solids elimination helps prevent the buildup of solids inside the drilling fluid, sustaining its wanted properties and minimizing have on on pumps together with other devices. This, consequently, minimizes downtime for repairs and maintenance. A nicely-preferred display also optimizes mud stream, avoiding tension drops and making certain reliable drilling overall performance. In addition, efficient solids Command cuts down the volume of waste created, decreasing disposal prices and minimizing environmental effects. By buying higher-top quality shaker screens which can be customized to your precise drilling specifications, it is possible to substantially increase performance, minimize expenditures, and enrich the overall accomplishment of the drilling operations.

In summary, picking out the right shaker display is vital for optimizing drilling operations. By thinking about things like drilling fluid sort, solids size, stream level, and shaker compatibility, you may select a screen that maximizes solids elimination efficiency and minimizes downtime. knowing the different sorts of shaker screens as well as their apps allows you to make knowledgeable decisions which have been tailored to the distinct desires. As you move forward, bear in mind investing in high quality shaker screens from the trusted shaker monitor manufacturer is undoubtedly an expense while in the prolonged-phrase effectiveness and accomplishment of the drilling functions. Don’t hesitate to consult with industry experts to ascertain the most effective Answer for your exclusive worries and optimize your drilling procedure.

Richard Thomas Then & Now!

Richard Thomas Then & Now! Melissa Sue Anderson Then & Now!

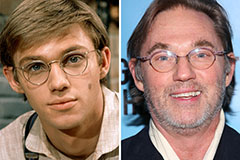

Melissa Sue Anderson Then & Now! Mike Smith Then & Now!

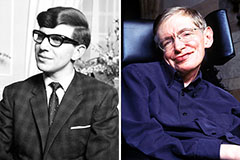

Mike Smith Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!